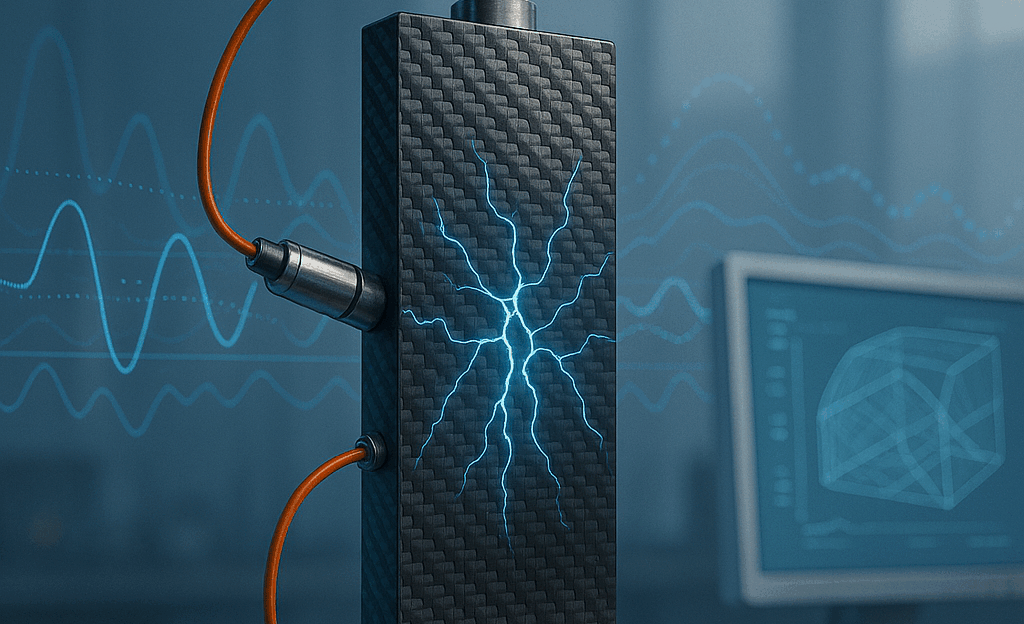

Structural composites are lightweight, strong and efficient, but predicting how long they will last remains a challenge. TRAIL explores how machine learning and non-destructive testing can be combined to monitor cracks and estimate remaining useful lifetime in fibre-reinforced thermoplastic composites.

Combining analytics with data-driven modelling

TRAIL focuses on long fibre-reinforced composites with semi-crystalline matrices. The project tests materials such as unidirectional carbon fibre laminates and others, to investigate whether crack formation and propagation can be detected through changes in electrical properties.

The method is first calibrated with the help of direct X-ray structural data. In a next step, the model is refined to predict internal damage without the need for direct structural information – relying instead on signal patterns and machine learning correlations.

Why this matters for industry

Understanding when a composite is likely to fail is essential for safety, maintenance and design. TRAIL contributes to smarter health monitoring strategies for polymer composites and paves the way for new approaches that extend the operational life of high-performance materials.

Part of DPI’s enabling research portfolio

TRAIL is part of DPI’s Enabling Tools & Technologies programme. It reflects our pre-competitive, collaborative and industry-driven approach to scientific research.

Boost your R&D

By joining the DPI community, you gain access to world-leading polymer research and you help shape it. Curious how this project fits your innovation roadmap? Let’s talk.

Claude Bostoen

Business development and programme manager

Questions or ideas?

Fill in the form and our programme manager will get back to you shortly.