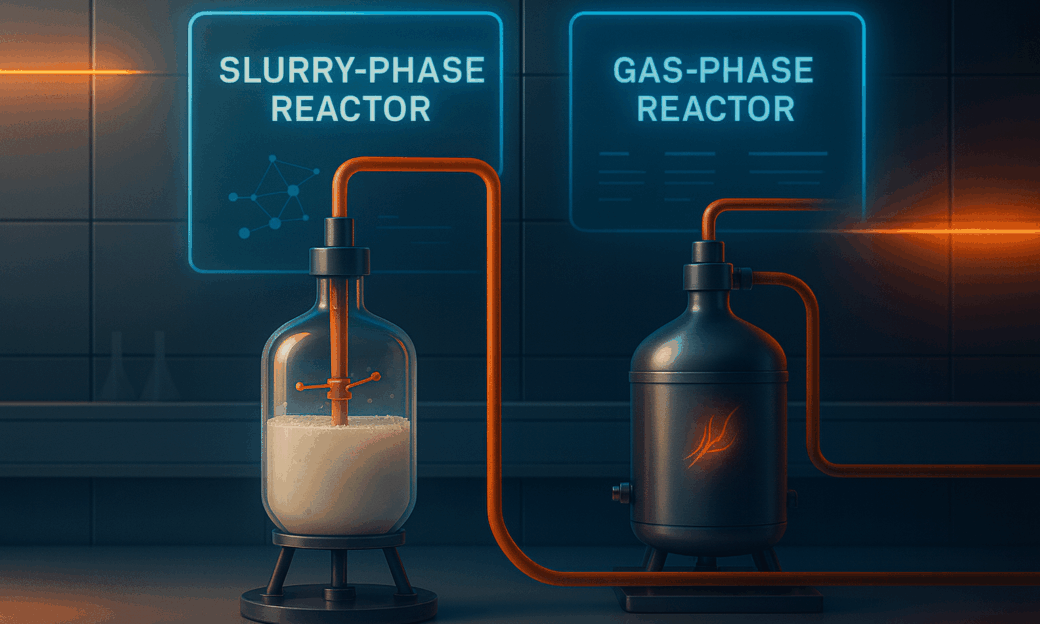

Translating catalyst performance from slurry-phase to gas-phase olefin polymerisation remains a persistent hurdle for industry. Despite using similar chemistries, these two reactor systems often produce markedly different results in terms of reaction kinetics and polymer properties. SLUGGER addresses this issue head-on by seeking to understand and model the root causes of this discrepancy.

The project aims to develop a reliable protocol for predicting gas-phase reactor behaviour based on data from laboratory and pilot-scale slurry-phase experiments. This requires a combination of controlled testing and advanced modelling to uncover the factors that govern catalyst performance across reactor environments.

Integrated modelling and experimentation across reactor types

SLUGGER investigates ethylene polymerisation under industrially relevant conditions, both with and without a diluent, to simulate the differing environments of slurry and gas-phase reactors. The research team combines systematic experimentation with mechanistic modelling to identify the drivers behind observed performance differences.

By mapping how variables such as flow dynamics, temperature distribution and mass transfer affect catalyst activity, the project seeks to build a robust, data-backed framework for performance translation. This integrated approach is key to moving from observation to predictive capability.

Supporting scale-up and efficiency in polyolefin production

Polyolefins are a cornerstone of global polymer production. Being able to forecast catalyst behaviour across reactor types offers tangible benefits: reduced development timelines, lower operational risk, and more efficient use of resources.

SLUGGER contributes directly to these goals by equipping the industry with tools to bridge the gap between lab and plant, ultimately accelerating innovation and improving the predictability of polymer manufacturing processes.

DPI contributes to long-term, shared insight

SLUGGER is part of DPI’s Enabling Tools & Technologies programme, which develops methods that support innovation across the polymer industry. In this project, DPI facilitates collaboration between industrial and academic partners around a shared challenge: translating slurry-phase data into reliable gas-phase predictions. By bringing together expertise and resources in a pre-competitive setting, this project contributes to the development of broadly applicable models and insights.

Claude Bostoen

Business development and programme manager

Questions or ideas?

Fill in the form and our programme manager will get back to you shortly.