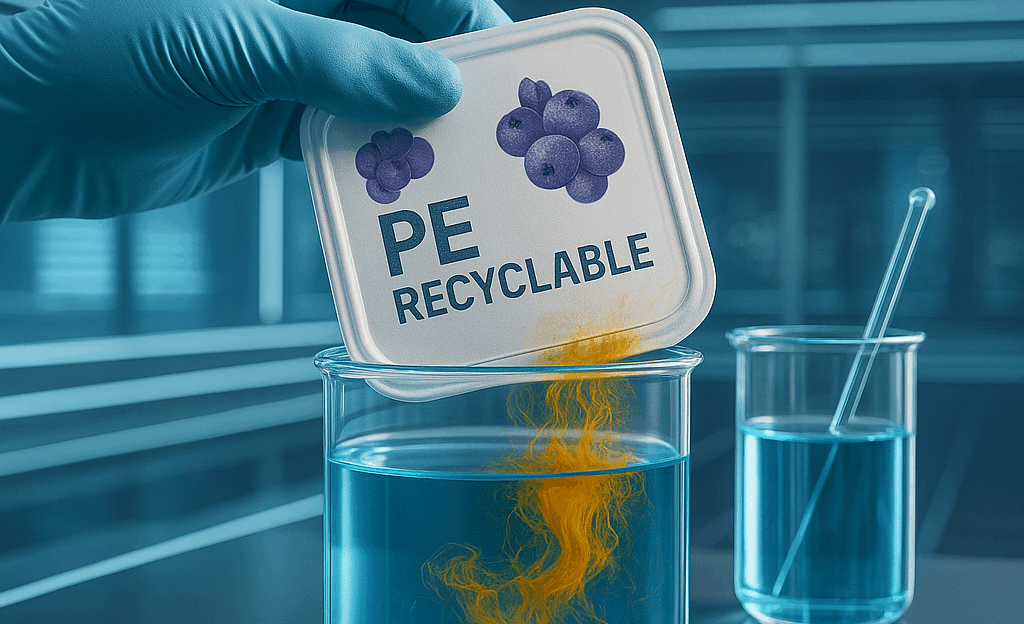

BioSolveCycle focuses on replacing toxic cleaning agents with bio-based solvents and surfactants that can effectively remove inks, adhesives, and additives from plastic waste streams such as food containers, flexible packaging, and electronics. By exploring new scavenging systems to prevent recontamination and staining, the project tackles one of the most persistent bottlenecks in polymer recycling. The outcomes will support food-grade applications, align with evolving EU regulations, and enable more sustainable recycling processes.

The project sets out to develop a fundamental understanding of polymer surface cleaning using bio-based media. Its goal is to identify formulations that are not only effective but also scalable and compliant, paving the way for closed-loop recycling systems in which polyolefins retain their value and function across multiple lifecycles.

Bio-based cleaning of polyolefins: a scientific exploration

The project explores the potential of bio-based solvents and surfactants for de-inking and delamination of multilayer and printed polyolefin materials. A key focus is preventing the re-adsorption of removed impurities — the so-called “bleeding” or “staining” problem — by integrating scavenging systems directly into the solvent media. This approach aims to provide a deeper understanding of the physical and chemical interactions governing polymer surface cleaning.

Expected outcomes: cleaner plastics and better recycling

BioSolveCycle is expected to deliver:

- Sustainable formulations for efficient decontamination of polyolefins

- A scientific basis for impurity scavenging mechanisms in solvent systems

- Insights that support safe, food-grade recycling of packaging plastics

- Potential guidelines for industrial upscaling of bio-based cleaning methods

Why it matters: enabling closed-loop recycling of polyolefins

Polyolefins such as polyethylene and polypropylene are among the most widely used plastics, yet also the most difficult to recycle in high purity due to persistent contamination. BioSolveCycle supports a more circular use of these materials by targeting a major bottleneck: surface cleanliness. The project’s outcomes could reduce dependency on toxic solvents, align recycling practices with upcoming EU regulations, and help industry meet consumer and legislative expectations for e.g. for safer, greener packaging.

DPI’s contribution: shaping pre-competitive collaboration

DPI facilitates the collaborative foundation of this pre-competitive project, bringing together expert researchers and industrial partners to co-develop solutions that benefit the entire value chain. As part of the Sustainable polymer materials programme, BioSolveCycle contributes directly to DPI’s mission to accelerate sustainable innovation in polymer science.

Denka Hristova-Bogaerds

Chief programme officer

Questions or ideas?

Fill in the form and our programme manager will get back to you shortly.