Innovating in the polymer industry requires precision, speed, and a deep understanding of material behaviour. The Enabling tools & technologies programme tackles this challenge by developing and integrating advanced modelling, high-throughput experimentation, and artificial intelligence. This programme provides essential insights into polymer behaviour like rheology, aging, fatigue, and creep, empowering industrial partners to drive the next generation of polymer materials and applications.

The Enabling tools & technologies programme enables breakthrough innovation through:

- Modelling & simulation: understanding and predicting polymer behaviour in diverse conditions.

- High-throughput experimentation: rapid screening of material properties for efficient development.

- Artificial intelligence & machine learning: enhancing material design speed and predictive analytics.

- Explorative chemistry & materials research: novel polymer materials pushing the boundaries of polymer science.

- Polyolefin catalysis & reactor engineering: optimising the polyolefin production processes

- New analytical tools: unlocking deeper insights into polymer properties and applications.

Through these capabilities, the programme strengthens industrial partners’ research strategies, reducing development timelines and increasing innovation success rates.

Key research areas and active projects

Advanced catalysis & polymer chemistry

ZN-TCLB

Developing next-generation Ziegler-Natta catalysts with temperature-controlled composition tuning, increasing precision in polymer production.

C1_QSPR

How do you steer catalyst behaviour when your system has more than one active site? That’s the challenge at the heart of C1_QSPR project, exploring how C1-symmetric catalysts behave in olefin copolymerisation, where multiple active sites may compete, and how to predict that behaviour before synthesis even begins.

View projectNext-generation analytical tools & AI-driven materials research

TRAIL

TRAIL combines electrical sensing and machine learning to monitor damage in fibre-reinforced thermoplastic composites.

View project

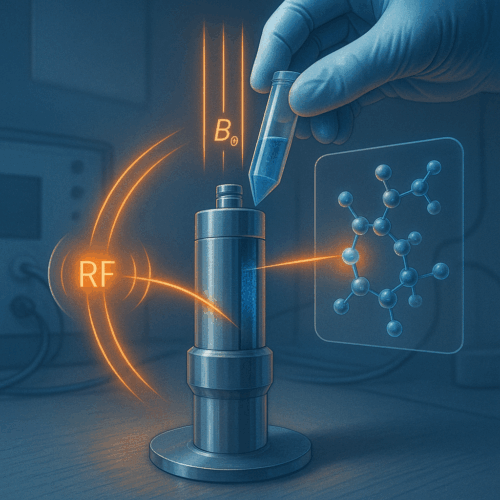

HYPERFAST 2

HYPERFAST 2 applies ultrafast MAS NMR to study polymer–fibre interfaces and improve resolution in polymer characterisation.

View project

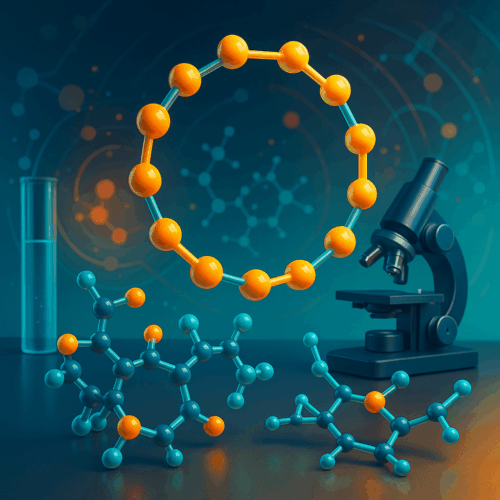

Topological Performance Polyolefins (TPPO)

TPPO explores how cyclic polyolefins can improve the performance of industrial resins. The project focuses on advanced synthesis and the rheological behaviour of new polymer topologies.

View projectPolymer ageing & mechanical performance

MORPHORMANCE

Understanding load-induced morphological changes in PEEK and their effects on creep and fatigue behaviour, supporting high-performance applications.

PEARL

PEARL uses molecular simulation to investigate how physical ageing and chemical degradation affect the behaviour of glassy polymers.

View projectReactor engineering & process optimisation

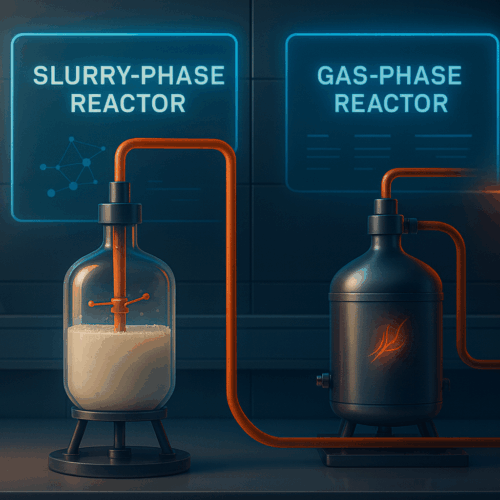

SLUGGER

SLUGGER explores how catalyst performance in slurry-phase reactors can be translated to gas-phase conditions. The project combines modelling and experimentation to support better reactor understanding and scale-up decisions.

View project

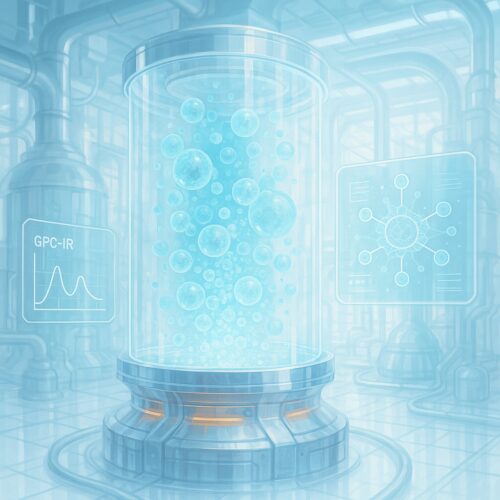

CASAFA

CASAFA investigates the root causes of fouling in fluidised bed reactors — from heat stress and triboelectrification to particle dynamics. Combining lab experiments with AI-powered analysis, the project delivers predictive insights to help industry prevent wall-sheeting, reduce downtime, and boost process stability.

View projectBoost your R&D with DPI

By joining the DPI community, you gain access to pioneering tools that accelerate material development: AI, modelling, high-throughput experimentation, and cutting-edge analytical methods.

Curious about how this could enhance your R&D? Let’s discuss opportunities!

Claude Bostoen

Business development and programme manager

Programme partners

Latest updates

If you just deliver on business needs, you might miss out on tomorrow’s trends

“It’s a huge risk to mistake a symptom for the actual problem”

Five new projects launched at the DPI Autumn Meeting 2025

Fresh perspectives boost QSPR research on catalyst prediction

Questions or ideas?

Fill in the form and our programme manager will get back to you shortly.